Today's Notables

Tokushu Kika and the Japan Quality Award

April 2005

Hisashi Furuichi

President and C.E.O.

Tokushu Kika Kogyo recently started applying for Japan Quality Award. Japan

Quality Award Council which is run by Japan Productivity Center

for Socio-economic Development recognizes excellence in management

performance every year by awarding JQA to a corporation that has

achieved outstanding performance in Japan. JQA award was established

in Japan after the Malcolm Baldridge national quality award was

started in the US in 1987.

Right after the war, Japan was able to bring itself up from the

ashes and begin manufacturing again. Initially, industry could only

manage to produce inferior goods and knockoffs when "Made in

Japan" became synonymous with producing fakes. However a diligent

and industrious Japanese workforce soon learned the advanced technology

of the West and became highly skilled at enhancing productivity

through technological advances. Soon, "Made in Japan"

had a whole different meaning: high quality goods manufactured through

efficient processes. Now, Japanese industry became the leader in

manufacturing goods of top quality.

Harvard professor Ezra Vogel published "Japan as Number One"

in 1979 in which he demonstrates how Japanese automobile and electronics

industries were able to make the transformation from a negative

"Made in Japan" image to one where just the brand names

meant high quality and reliability beginning in the latter half

of the 1970s. Furthermore, Japanese corporations were also adept

at accurately assessing the customer and market needs; then reflecting

those needs in the form of quality improvements and greater efficiency,

quickly and more consistency than other countries. Japan had developed

the "new industrial revolution" model, setting the standards

for the world.

During the 1980's, on the other hand, American industry began to

lag behind in competitiveness. To determine the cause and stop the

decline, the US Department of Commerce appointed several top economists

and experts to research the cause and find a solution. Naturally,

they studied Japan's high productivity along with taking a comprehensive

approach to finding causes for the decreasing competitiveness of

American-made goods. Then in 1988, the Malcolm Baldridge national

quality award was established using these research results as a

basis to develop a common yardstick to evaluate total process and

product quality. The award was named after Malcolm Baldridge who

was then Secretary of Commerce under the Reagan Administration.

While American companies worked to revive industry toward the goals

of the Award, the economic bubble in Japan burst, causing severe

changes in structure of world markets and shaking the very foundations

of industry. This called for a radical reform of management. The

JQA was one of the outcomes that arose from studying how Japan needed

to fundamentally change management in order to meet the new challenges.

Many standards in the ISO Quality Management System were also based

on the study of Japan's high quality standards but it is the JQA

standards that were modeled after Japanese corporations that have

shown excellence in performance.

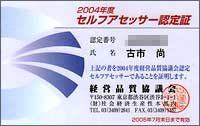

However lengthy, perhaps that explanation shows why the JQA is

one goal that TK should work toward. The JQA calls for a self assessment

which needs to be performed by trained personnel. Training seminars

are held in Tokyo and Osaka on an as-needed basis. I decided to

take the lead and attend a seminar on self-assessment myself. There

are three different grades: G1 (one day), G2 (2days) and G3 (3 days).

The certification seminar is 2 days in which Japan Quality Award

Council certifies someone as an assessor. Throughout the seminar,

you study the self-assessment guidelines and outline but most of

the time is spent in the practical work through groups and exercises

to develop practical skill. Although the group work is based on

case studies, there is a significant amount of content to be covered

so I had to use my brain more than usual. It was more difficult

that I had imagined.

Because the methods to improve the quality of management are unique

to the corporation, a consensus must be achieved through dialog.

Therefore, there is no "right" answer and you consider

the instructor's explanation and then mull it over in light of your

own experience. We will continue to send people to train as self-assessors

in order to achieve excellence in management quality and performance.

( Reference: "What is the JQA?," Japan Productivity Center

for Socio-economic Development )

HOME > What’s New > Today's Notables > Details